- Call Us : +86-15060765919

- Mail Us : bella@fespower.cn

As global EV adoption accelerates, charging power is rapidly increasing. From traditional 7 kW AC chargers to today's 350 kW+ ultra-fast charging systems, heat generation becomes a serious engineering challenge.

Cooling is no longer just a “design option” — it directly determines safety, charging speed, efficiency, and equipment lifespan.

For FES Power, cooling technology is a vital foundation in delivering stable, high-performance charging solutions.

❓ Why Do EV Chargers Need Cooling?

During charging, power modules, rectifiers, and charging cables generate substantial heat. Without proper cooling, chargers can:

⚠️ Lose efficiency and slow down charging

🔥 Shorten the lifespan of power components

🛑 Trigger over-temperature shutdowns

👎 Deliver a poor user experience

That’s why advanced cooling design is essential for every modern charging system.

❓ What Is Natural Cooling and Where Is It Used?

Natural cooling relies on air convection without any fans or pumps.

✨ Advantages:

📌 Best for:

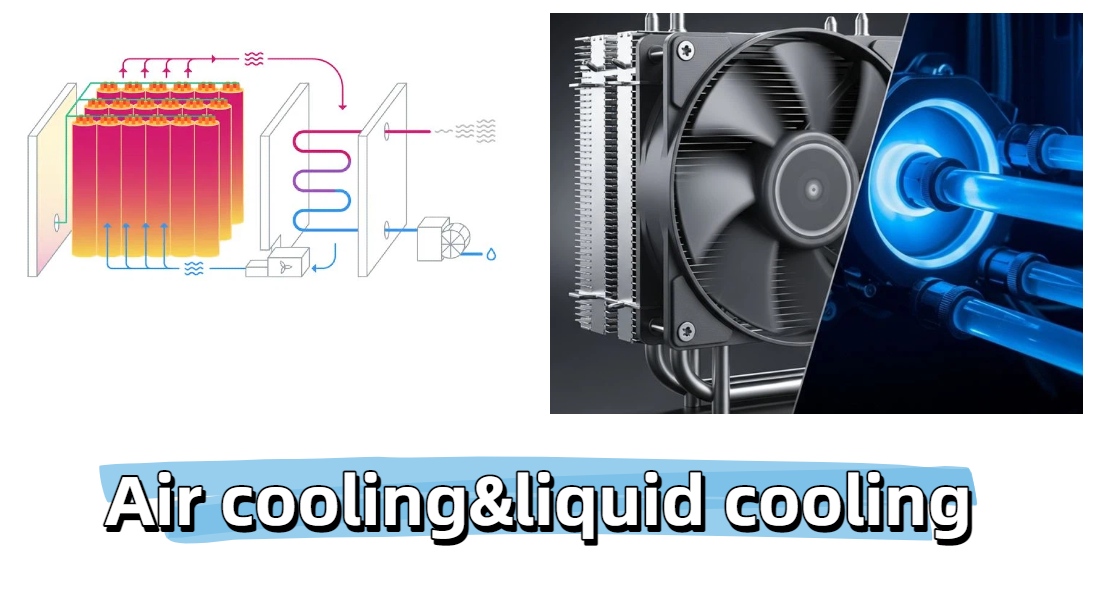

❓ How Does Air Cooling Work and Why Is It So Common?

Air cooling uses fans to push air through heat sinks and internal modules.

💡 Pros:

Moderate cost

Higher cooling efficiency than natural convection

📌 Typical for:

30–120 kW DC fast chargers

Modular DC chargers with integrated airflow paths

🚫 Drawbacks: Noise & dust accumulation requiring periodic cleaning.

❓ What Makes Liquid Cooling the Future of Fast Charging?

When charging power increases to 180 kW, 350 kW, or beyond, air cooling becomes insufficient.

Liquid cooling circulates coolant through cold plates to quickly remove heat.

💧 Key Advantages:

⚡ Widely adopted in ultra-fast charging stations and high-voltage (800V) EV platforms.

FES Power integrates advanced liquid-cooling designs into multiple high-power products to meet future charging demands.

❓ Why Are Liquid-Cooled Cables Necessary for Ultra-Fast Charging?

High-power charging requires extremely high current (500A–600A+).

Traditional cables overheat quickly, limiting charging speed.

Liquid-cooled cables solve this by circulating coolant inside the cable structure, enabling:

🔋 Higher current capacity

🚀 Faster charging

🛡️ Better thermal stability & cable lifespan

This technology is essential for 350 kW–600 kW ultra-fast chargers — and FES Power offers fully compatible solutions.

❓ Are There Any Other Cooling Methods?

In special or extreme conditions, additional cooling solutions may be used:

Though less common, these methods are crucial for high-demand industrial scenarios.

❓ How Do FES Power Products Reflect Cooling Advantages?

FES Power integrates advanced cooling technologies across its product line, visible on the official website:

🌬️ Modular Air-Cooled DC Fast Chargers (30–120 kW)

💧 High-Power Liquid-Cooled DC Systems (180 kW+)

⚡ Liquid-Cooled Cable Compatibility

These solutions reflect FES Power’s commitment to safety, reliability, and next-generation charging performance.

❓ Where Is Cooling Technology Headed in the Future?

The EV charging landscape is evolving rapidly. Expect innovations such as:

FES Power will continue investing in cooling innovation to support the next wave of ultra-fast charging infrastructure.